Inspecting Electrical Panels: What Do Home Inspectors Look For?

Date Published: August 4, 2025

In this day in age, electricity is a critical component in any household. The electrical panel essentially works as the heart of your electrical system – meant to safely and efficiently distribute electricity throughout the home.

During a standard home inspection, the electrical panel (often referred to as the “breaker box”) is a key focal point. When improperly installed or configured, the breaker box can be very dangerous. So what exactly does your inspector need to look for when inspecting electrical panels?

Inspecting Electrical Panels

Accessibility

Right off the bat, the inspector will be assessing the panel based on how easily it can be accessed. Obstructions will be called out, especially if the inspector can not physically get to the the box.

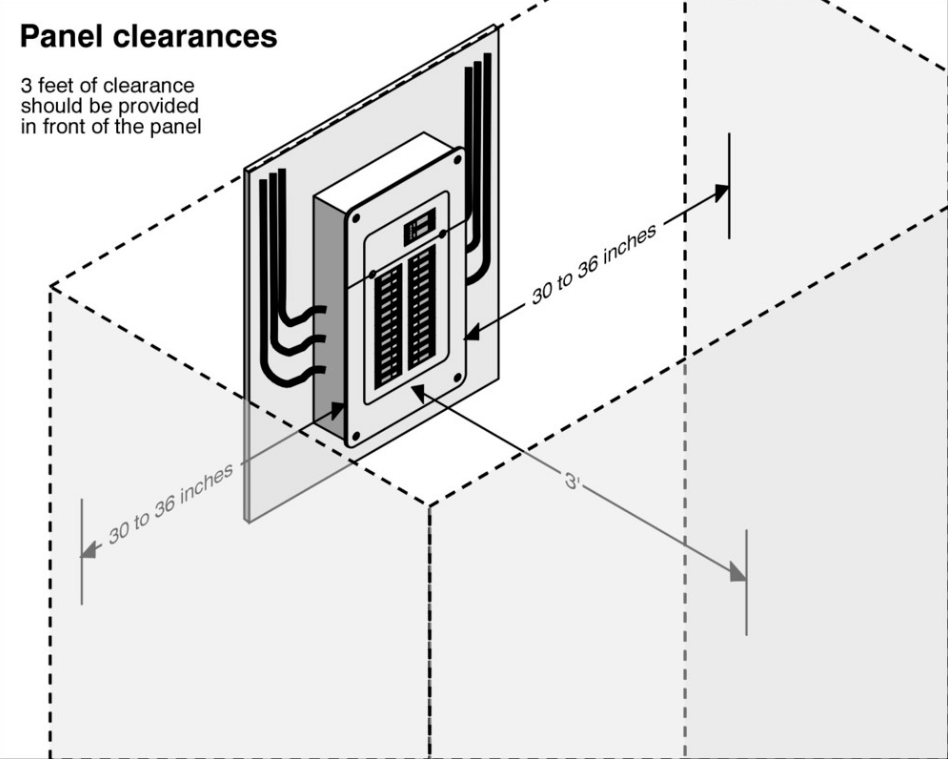

There should be at least 36 inches of clearance in front of the box, and 30-36 inches to its left and right. Additionally, nothing should be propped against it or stacked on top of it.

Panel Condition

The condition of the panel is crucial. Any significant defects could lead to serious safety hazards. We check for signs of water intrusion, rusting, corrosion, scorch marks etc.

Also how old is the panel? If the breaker box appears to be 30 years or older, we will call it out for further evaluation by an electrician.

There are also specific problematic brands to pay attention to. For instance, Federal Pacific (shown below), Zinsco, and Sylvania panels each had its own respective defects that proved to be serious fire hazards. If our inspectors detect these brands on the premise, they will call them out for immediate evaluation and replacement.

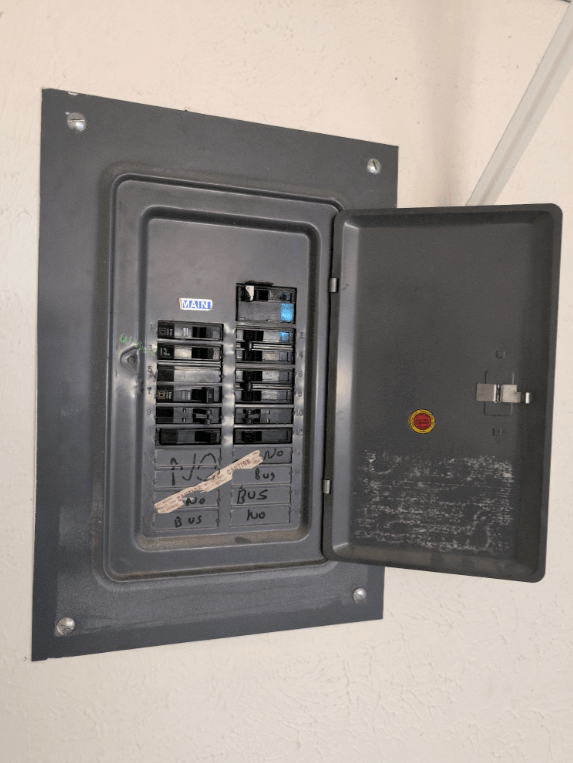

Proper Labeling

Our inspectors will make note of any breaker labels that are missing, incomplete, or faded. Proper labeling is important because it helps to ensure that the power is disabled correctly to any circuits or equipment while being serviced. Additionally, if any of the breakers trip, correct labeling will indicate the circuit or circuits that have been affected.

Correct Wiring and Breakers

This is a big one. During a standard inspection, our inspectors remove the panel cover in order to examine the wiring. All hot, neutral and grounds must be configured properly. And any signs of improper or hazardous wiring will surely be flagged.

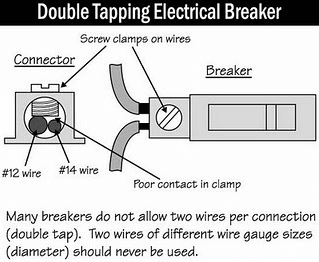

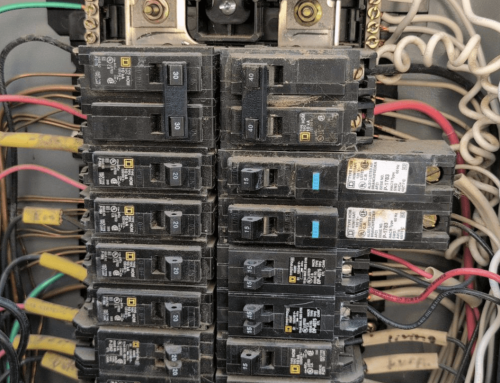

A common defect we see is double tapping – where two or more conductors are connected to one breaker (shown below). This is not allowed, and should be corrected for safety. An electrician should evaluate and repair this item.

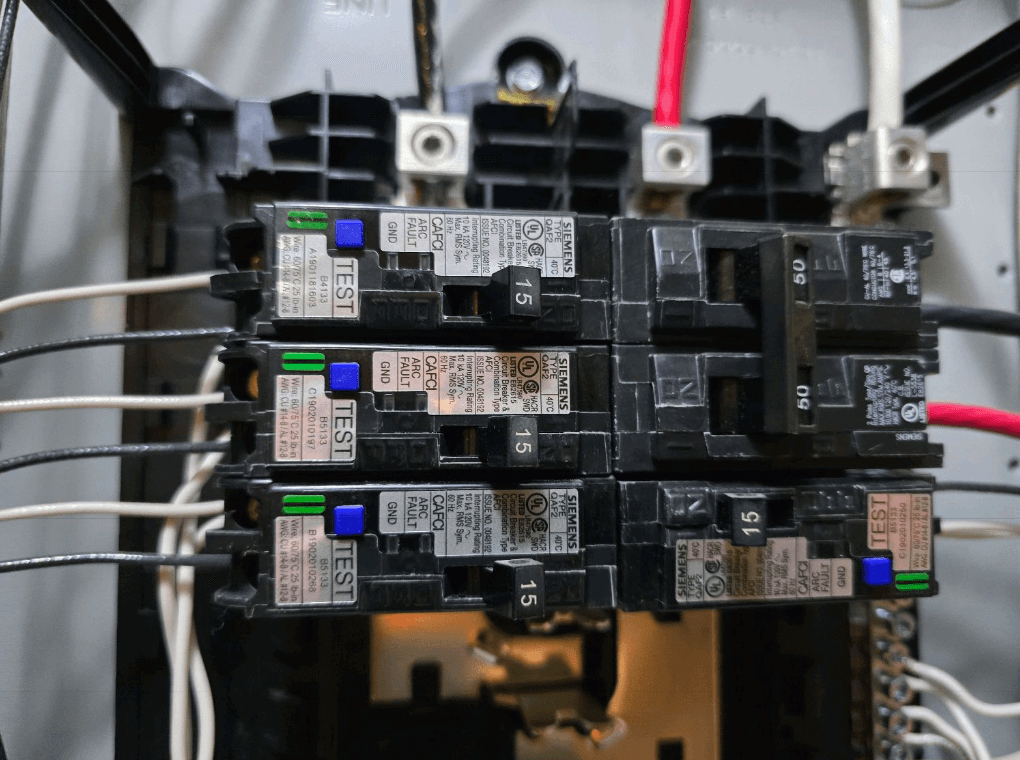

We are also on the look out to make sure that all the breakers are the same manufacturer as the panel itself. Incompatibilities between breaker and panel manufacturer can cause electrical arcing and performance issues.

The breakers should be properly sized for their wiring circuits. When oversized, the wiring could overheat without the breaker tripping, creating a potential fire hazard.

We will also test AFCIs and GFCIs when they are present on the breakers. However, many older panels do not have ACFIs, and GFCIs are commonly found directly on outlets within the house.

Furthermore, it is crucial to be on the lookout for aluminum wiring. This material was widely used in the ’60s and ’70s as a cheap alternative to copper. But it soon became clear that this material is highly susceptible to corrosion and oxidization. Needless to say, this is a red flag for any inspector!

Amperage Rating

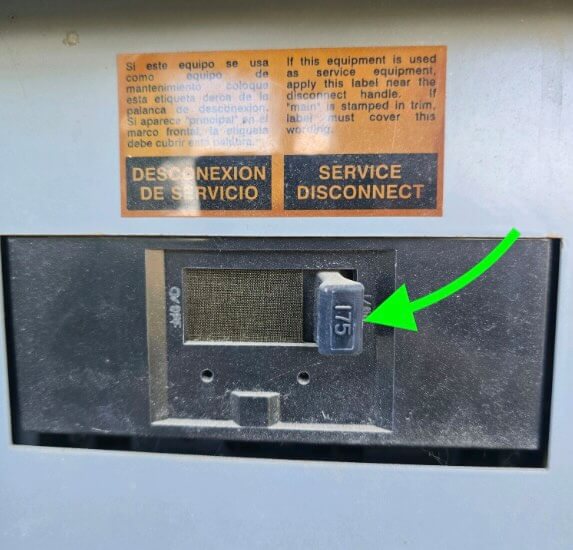

The inspector will be sure to look at the main service amperage rating, to make sure it is sufficient for the household. The average home should have at least 200 amps, with some smaller apartments only needing around 100 amps.

We sometimes see older homes with inadequate services amperages. While this may have been adequate when the home was built, this can prove to be an undersized electrical service for modern electrical needs. In these cases, the service conductors running to the home will likely need to be replaced, and the main panel will also need to be replaced with a higher capacity panel.

DIY or Non-Standard Installations

When inspecting electrical panels, any type of sloppy or seemingly unprofessional alterations or wiring may raise concern. Any improperly stripped or exposed wires will be noted. Also all unused knockouts should be covered to avoid pest or moisture intrusion.

Essentially anything that might seem out of the ordinary will likely be called out, just to be safe. When in doubt, call it out!

What Home Inspectors DO NOT Inspect

While our home inspectors can give you a comprehensive overview of the electrical system, they are not certified electricians, which means they do have limitations.

For instance, we do not remove breakers or wiring to inspect behind them. We don’t perform load calculations or test individual circuits.

If the home has an older breaker box, and you wish to verify code compliance, we will recommend that you consult with a specialist. And of course, we do not perform any repairs or upgrades.

Scott Home Services: Inspecting Electrical Panels and Beyond!

We hope that this article has given you a better insight into our electrical inspecting procedure. However, our standard home inspections don’t stop there – we inspect all major aspects of a residence.

For a full breakdown of our inspection process, check out this article!

If you are located in the Colorado Front Range and are in need of a home inspection, we hope that you’ll give Scott Home Services a try! We proudly offer an extensive list of home services, such as radon testing, sewer scope inspections, energy evaluations, mold testing and more!

Feel free to visit us online, or contact us to book your inspection services today!

Related Articles

If you enjoyed this article, you may be interested in some of our others.